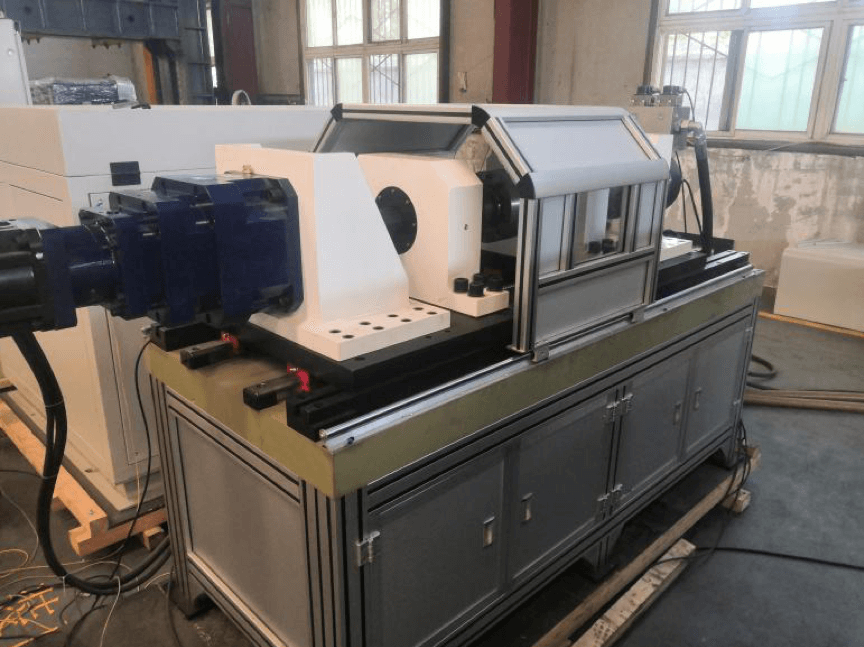

Clutch fatigue test and equipment platform

The clutch labor testing machine is mainly used to test the mechanical properties of various clutches such as fatigue life, expansion fatigue, endurance fatigue, fatigue strength, etc. According to the standard:

General technical requirements for GB/2611 testing machine

GB/T16826 Electro-hydraulic servo universal testing machine

GB3075 Metal Axial Fatigue Test Method

Technical conditions of JB/9397 tension and compression fatigue testing machine

GB228 Room temperature tensile test method for metallic materials

Platform: The platform we introduced from Taiwan in October 2020

Features:

1 Test machine host: Two uprights, bases, and beams form a closed frame structure. The frame has high rigidity, no backlash, and good stability. The outer surface of the double column is treated with electroplating hard chrome, the servo actuator (cylinder) is placed underneath, and the two-way acting cylinder piston design is adopted, and the specimen clamping adjustment is convenient and flexible.

2 Hydraulic servo pump station: Adopting no leakage and silent technology, stable pressure output, no fluctuation and low noise, good heat dissipation effect, high filtration precision, automatic protection of pressure overload and oil temperature over temperature.

3 Control mode: PID closed-loop control of force, displacement and deformation, and can realize undisturbed switching of flat bones in any control mode

4 Test waveforms: sine wave, square wave, triangle wave, cotton ladder formation, ramp wave, user-defined liquid shape, etc.

Maximum static test force ±10kN

Maximum dynamic test force ±10kN

Maximum stroke displacement of actuator ±50mm

Operating frequency range 0.01-10HZ

Main experimental waveforms: sine wave, square wave, triangle wave, cotton ladder formation, oblique wave and various component waves

Experimental space ≥500mm