Features:

BREU(K) freewheel cam clutch bearing is a kind of freewheel one way clutch, installed in the rear crankshaft or flywheel center hole, the role is to guide, in the clutch separation state to prevent a shaft radial runout. The engine pitch passes through the flywheel, clutch housing, pressure plate and clutch driven plate to one shaft.

When enabled, the conversion time of the automated racing gearbox is extremely short and the bearings allow exposure to very high speed gradients. This also brings special requirements for bearings and bearing lubricants. Choosing the right bearing design, grease and even coating at this location is critical to the robustness and reliability of the solution.

Product parameter:

| Model | Torque Capacity(N·m) | Inner Race Overrunning Speed | Max. Engagement |

| Min. (r/min) | Max. (r/min) | Speed (r/min) |

| BREU 30 (K) | 607 | 880 | 3600 | 350 |

| BREU 35 (K) | 686 | 780 | 3600 | 300 |

| BREU 40 (K) | 980 | 720 | 3600 | 300 |

| BREU 45 (K) | 1078 | 670 | 3600 | 280 |

| BREU 50 (K) | 1715 | 610 | 3600 | 240 |

| BREU 55 (K) | 1960 | 580 | 3600 | 220 |

| BREU 60 (K) | 3479 | 490 | 3600 | 200 |

| BREU 70 (K) | 4735 | 480 | 3600 | 200 |

| BREU 80 (K) | 6517 | 450 | 3600 | 190 |

| BREU 90 (K) | 8526 | 420 | 3000 | 180 |

| BREU100 (K) | 14210 | 460 | 2500 | 180 |

| BREU130 (K) | 20384 | 420 | 2200 | 180 |

| BREU150 (K) | 33908 | 370 | 1300 | 180 |

| Model | Bore Size(H7) | Keyway(Inner Race) | A | B(h7) | C | D | E | F | G | H-J | K | L | b | t1 | Weight(kg) |

| BREU 30 (K) | 30 | 8 × 3.3 | 76 | 100 | 51 | 87 | 75 | 45 | 56 | 6-M6 | 10 | 1 | 8 | 4 | 2.7 |

| BREU 35 (K) | 35 | 10 × 3.3 | 79 | 110 | 50 | 96 | 80 | 50 | 56 | 6-M6 | 12 | 1 | 10 | 5 | 3.2 |

| BREU 40 (K) | 40 | 12 × 3.3 | 86 | 125 | 53 | 108 | 90 | 55 | 59 | 6-M8 | 14 | 1.3 | 12 | 5 | 4.4 |

| BREU 45 (K) | 45 | 14 × 3.8 | 86 | 130 | 53 | 112 | 95 | 60 | 59 | 8-M8 | 14 | 1.3 | 14 | 5.5 | 4.7 |

| BREU 50 (K) | 50 | 14 × 3.8 | 94 | 150 | 64 | 132 | 110 | 70 | 72 | 8-M8 | 14 | 1.3 | 14 | 5.5 | 7.6 |

| BREU 55 (K) | 55 | 16 × 4.3 | 104 | 160 | 66 | 138 | 115 | 75 | 72 | 8-M10 | 16 | 1.5 | 16 | 6 | 8.9 |

| BREU 60 (K) | 60 | 18 × 4.4 | 120 | 170 | 84 | 150 | 125 | 80 | 95 | 10-M10 | 16 | 1.5 | 18 | 7 | 12.5 |

| BREU 70 (K) | 70 | 20 × 4.9 | 134 | 190 | 95 | 165 | 140 | 90 | 108 | 10-M10 | 16 | 1.8 | 20 | 7.5 | 17.2 |

| BREU 80 (K) | 80 | 22 × 5.4 | 144 | 210 | 100 | 185 | 160 | 105 | 108 | 10-M10 | 16 | 1.8 | 22 | 9 | 22.4 |

| BREU 90 (K) | 90 | 25 × 5.4 | 158 | 230 | 115 | 206 | 180 | 120 | 125 | 10-M12 | 20 | 2 | 25 | 9 | 30.3 |

| BREU100 (K) | 100 | 28 × 6.4 | 186 | 270 | 124 | 240 | 210 | 140 | 135 | 10-M16 | 24 | 2 | 28 | 10 | 45.5 |

| BREU130 (K) | 130 | 32 × 7.4 | 212 | 310 | 152 | 278 | 240 | 160 | 168 | 12-M16 | 24 | 2.5 | 32 | 11 | 67 |

| BREU150 (K) | 150 | 36 × 8.4 | 246 | 400 | 180 | 360 | 310 | 200 | 194 | 12-M20 | 32 | 2.5 | 36 | 12 | 145 |

Installation and Usage:

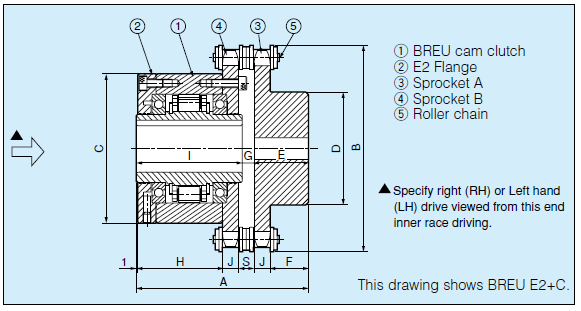

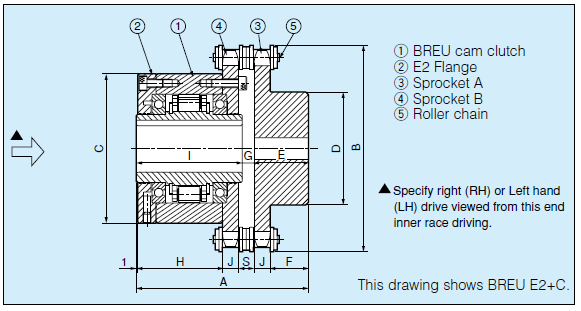

1. BREU-(K) C series Cam Clutch couplings make use of BREU series Cam Clutch and CRtype couplingswithout cover.

2. Mount the clutch loosely on the high-speed shaft at first.

3. Accurately align both sprockets by checking with a straight edge on the teeth of both sprockets.

4. Check whether the clearance(S) between the two sprockets is correct, then wrap the chain around thesprockets.

5. Specify right hand (RH) or left hand (LH) as inner race overrunning direction from the view of cam clutch side.

6. The same lubrication as for Tsubaki roller chain is necessary for the coupling chain.

7. Ensure that the chain is properly closed with a connecting link and that the closed of the spring clip is installedin the same direction as the rotation of the outer race.

Lubrication

BREU series Cam Clutches need periodic maintenance and lubrication to both bearing to provide maximum performance throughout their service life. Lack of prescribed maintenance and lubrication will shorten the Service life of Cam Clutch and may cause unnecessary mechanical damage.

Recommended Grease

Brand | AmbientTemperature |

–5°C~+40°C | –40°C~+40°C |

Esso | — | Beacon325 |

Mobil | — | MobiltempSHC100 |

Shell | AlvaniaGreaseS2 | AlvaniaGreaseRA |

BP | EnergreaseLS2 | EnargreaseLT2 |

TOTAL | Multis2 | Aerogrease22 |

Note: Do not use Grease that contains EP additives.

E1~E7 options are supplied with bolts for installation, and the grease nipple.

Maintenance

BREU series Cam Clutches are pre-greased at the factory and should be re-greased every three months for bothbearings after installation. Follow the procedure below.

1. Remove the set screw at the flange, torque arm or cover.

2. Inject equal amounts of grease into the bearing from the grease nipple. Refer to the grease volume table forthe correct amount.

3. Run the Cam Clutch disengaged for from 20 to 30 minutes with the set screw removed. Excess of grease inthe clutch area will flow out of the tapped holes. Be careful to avoid over greasing. Too much grease in the

clutch will cause it to run hot, interfere with the clutch action, and may lead to mechanical damage.

4. Wipe off excess of grease and re-install the set screw.

Product display: