DLK Electromagnetic Brake Dry Type Multidisc Electromagnetic Clutch

- Phone: 18019694558

- Email: sales@backstopclutch.com

DLK Electromagnetic Brake Dry Type Multidisc Electromagnetic Clutch

- Phone: 18019694558

- Email: sales@backstopclutch.com

Main use:

Electromagnetic singiedisc clutches/brakes has one friction pair,it has festures of simple in structure,convient in installation,high in work frequency,agile in actuation,non-drag torque and low noise etc,widely use in the machinery driving systems of printing ,papermaking ,pack-aging,medical treatment ,texitile ,construction,boats and ships,office machine,the outer equipment of the computer,meter and instrument,communication etc,realize the functions of engaging and disengaging,reversing changing the directions,braking,positioning etc.

Product parameter:

| SIZE | rated dymanic torqueN.m | drag torque(N.m) | engagement time | disengagement time | rated voltage (DC V) | coil consumption power(20°)W | allowed max revolvtion(r/min) | weight(kg) |

| DLK1-2.5 | 25 | 0.1 | 0.1 | 0.03 | 24 | 16.5 | 3500 | 2 |

| DLK1-5 | 50 | 0.2 | 14 | 0.04 | 24 | 20.5 | 3000 | 3 |

| DLK1-10 | 100 | 0.3 | 0.16 | 0.06 | 24 | 28.8 | 3000 | 4.5 |

| DLK1-16 | 160 | 0.8 | 0.2 | 0.1 | 24 | 48 | 2500 | 5.9 |

| DLK1-25 | 250 | 1.2 | 0.27 | 0.15 | 24 | 53 | 2200 | 8.95 |

| DLK1-40 | 400 | 2.0 | 0.35 | 0.2 | 24 | 62 | 2000 | 13.45 |

| DLK1-80 | 800 | 4.00/2.20 | - | - | 24 | 79 | - | - |

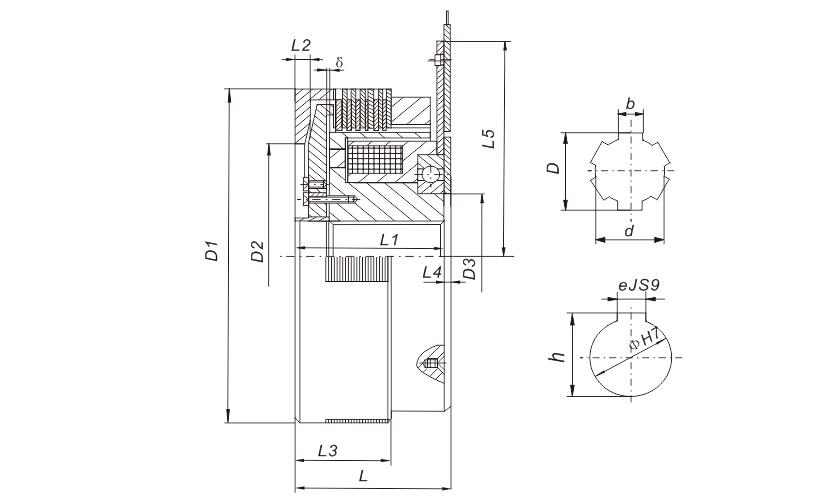

| SIZE | Radial Demensions(mm) | Axial Demensions(mm) | ||||||||||||||

| D1 | D2 | D3 | D | d | b | Φ | e | h | L | L1 | L2 | L3 | L4 | L5 | δ | |

| DLK1-2.5 | 100 | 75H9 | 40 | 25 | 21 | 5 | 25 | 8 | 28.3 | 50 | 44.5 | 30 | 4 | 4 | 79 | 0.2±0.05 |

| DLK1-5 | 115 | 85H9 | 48 | 30 | 26 | 6 | 30 | 8 | 33.3 | 56 | 50.5 | 35 | 4 | 5 | 83 | 0.25±0.05 |

| DLK1-10 | 135 | 95H9 | 55 | 40 | 35 | 10 | 40 | 12 | 43.3 | 60 | 56 | 40 | 4 | 6 | 89 | 0.3±0.05 |

| DLK1-16 | 150 | 105H8 | 60 | 45 | 40 | 12 | 45 | 14 | 48.8 | 66 | 60 | 44 | 3 | 7 | 97 | 0.3±0.05 |

| DLK1-25 | 172 | 120H9 | 65 | 50 | 45 | 12 | 50 | 14 | 53.8 | 72 | 64 | 48 | 3.5 | 8 | 105 | 0.35±0.05 |

| DLK1-40 | 202 | 130H9 | 80 | 60 | 54 | 14 | 60 | 18 | 64.4 | 81.5 | 73 | 52 | 4.5 | 8 | 117.5 | 0.35±0.05 |

| DLK1-80 | 240 | 180H7 | - | - | - | - | 68 | 20 | 72.9 | 99 | 91 | 74 | - | 11 | 150 | 0.4 |

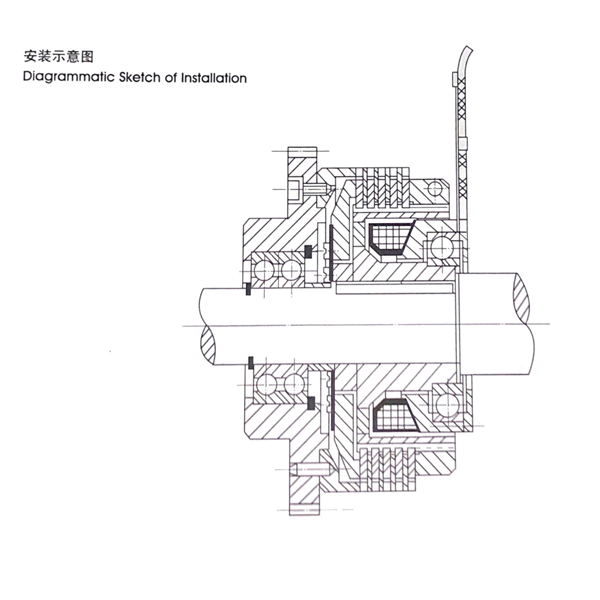

Mounting example:

Installation:

1. before mounted,clean the friction surface,ensure that there has no dust and other.

2. When mounted,the axial direction must be fixed,if mounted one by one,the coaxial de-gree should be maintained 9 grads.

3. While mounting ,adjusted the air gap to make it up to the fixed value in the form.