DLMS-16A Electromagnetic Clutch 24V Mini Electromagnetic Clutch

- Phone: 18019694558

- Email: sales@backstopclutch.com

DLMS-16A Electromagnetic Clutch 24V Mini Electromagnetic Clutch

- Phone: 18019694558

- Email: sales@backstopclutch.com

Main use:

DLMS-16A Electromagnetic multidisc clutches for wet operation with slipring or non-slipring,worked at the lubricated condition,having fatures of little wear in friction lining,long in service life,small in radial demensions,,large in torque,the can be widely used in the machinery driving systems of the equipments of machine tools,steel rolliing,metallurgy ,mining,metal pressuring and exteding,removing,boats and ships and fishery etc,and realize the function of rngaging and disengaging ,reversing and changing speeds etc.

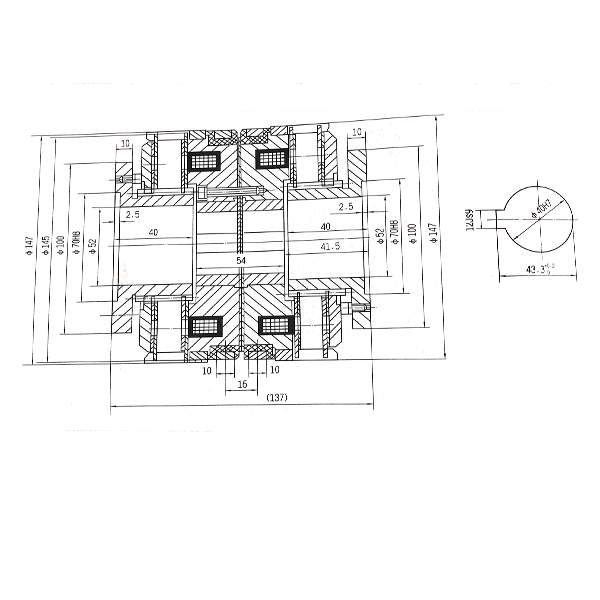

Components And Parameters:

| SIZE | rated dymanic torqueN.m | rated statictorque(N.m) | rated voltage (DC V) | coil consumption power(20°)W |

| DLMS-16A | 160 | 176 | 24 | 38 |

Conditions:

1.The elevation atitude of the clucth installation place doesn't exceed 2000nm.

2.Ambient envirmental temperature is between -5 °C to +40°C.

3.Around the medium,there is no gas and conductive dust that has nonbursting danger ans can't corrode metal and damage the insulator.

4.The voltage fluctuation of the clutch coil can't exceed -5 present to -15 present of the rated vlotage.

5.lubrications is needed between friction lining.

Installation:

1. the clutch must be washed clean before installation.

2.Axial direction should be fixed when mounted,if mounted axle one by one,the coaxial de-gree should be up to 9 grades.

3. While the clutch is working ,the oil must be supplied to the friction discs,ubder th ehigh speed revolution and high frequency operation,the method of axle center supplying oil should be adopted,the capacity of oil ,pls see the figure.

4. The lubricating oil of the clutch must be cleaned or it will affect the operation reliability.