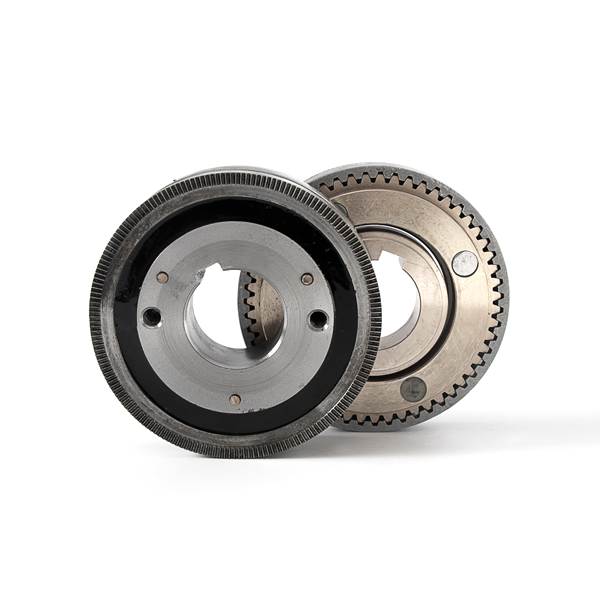

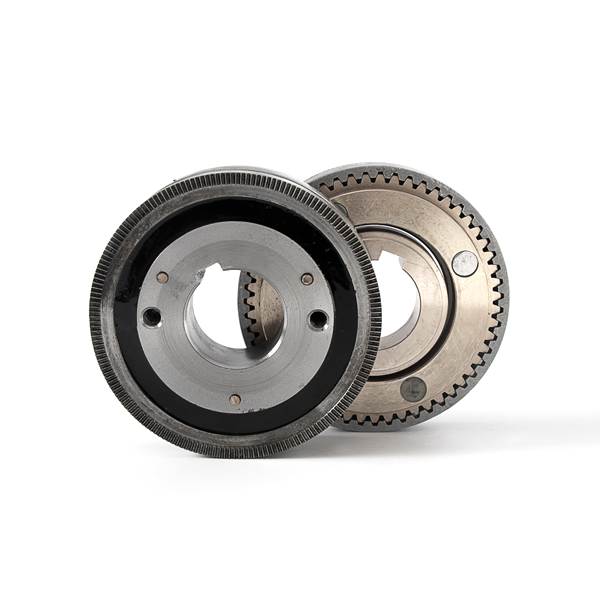

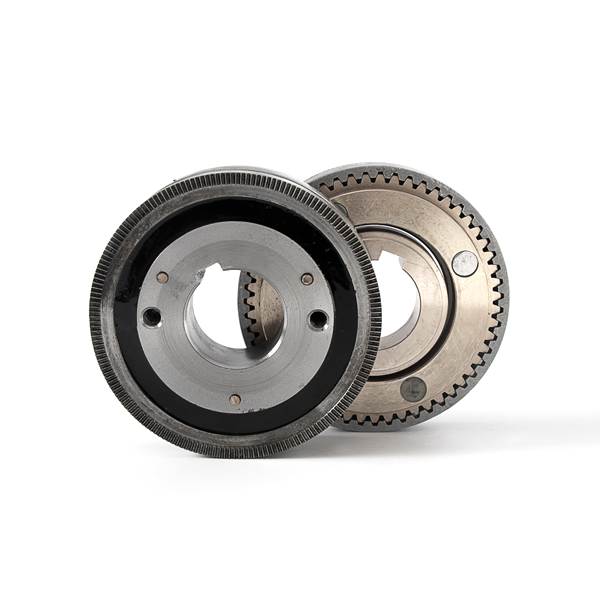

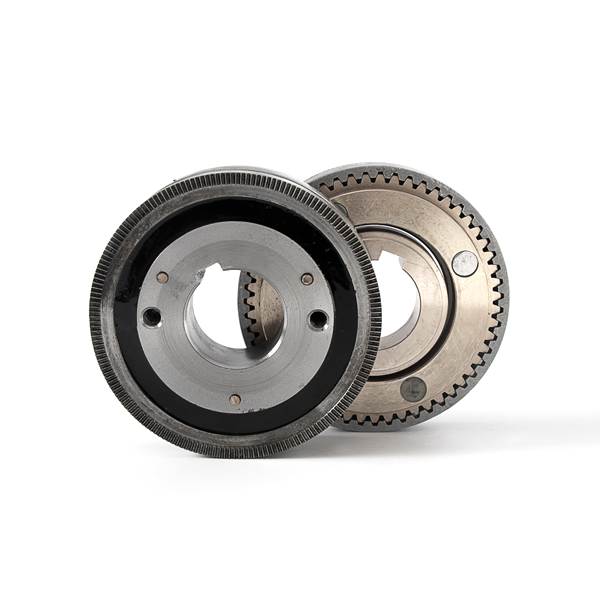

Main use:

When the relative revolution of the driving and the driven of parts is lower or zero,the micro electromagnetic clutch makes them combination,thus realize the purpose of starting and stopping ,changing the directions and positioning etc.The clucth is mainly used in machinery driving system,and widely in metal processing machine,metallurgy,steel rolling machine,packing machine,medical machine,food processing machine textile and printing and dying machine,papermaking machine,precision machine tool etc.

Components And Parameters:

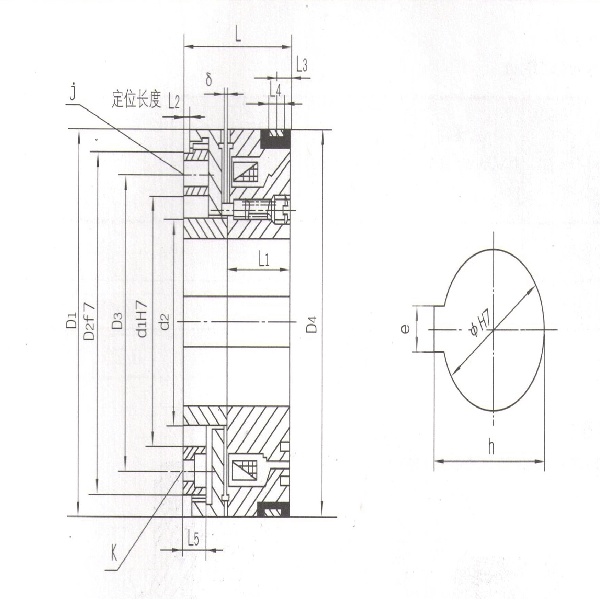

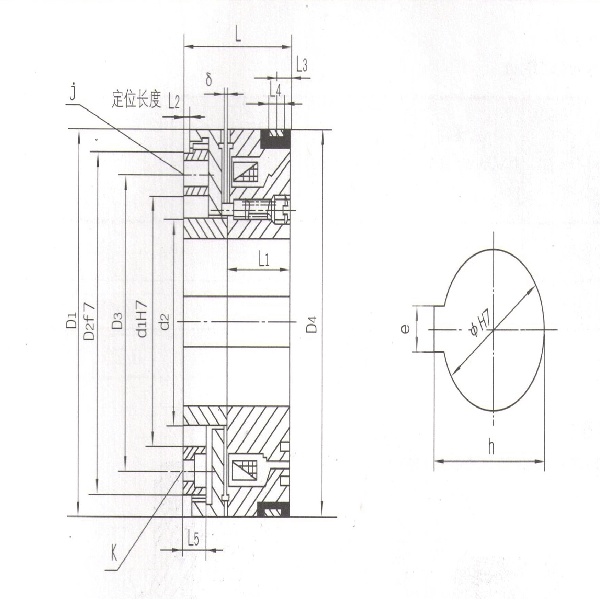

| SIZE | Radial Demensions | Axial Demensions |

| D1 | D2 | D3 | D4 | d1 | d2 | Φ | h | e | j | k | L | L1 | L2 | L3 | L4 | L5 | δ |

| DLY5-2A | 75 | 65 | 55 | 75 | 45 | 39.5 | 25 | 27.6 | 8 | 2*4 | 4-M4 | 33 | 18.6 | 1.5 | 6.5 | 8 | 8 | 0.4 |

| DLY5-5A | 90 | 75 | 64 | 90 | 53 | 49 | 30 | 32.6 | 8 | 2*5 | 4-M5 | 40 | 24.1 | 2 | 6.5 | 8 | 9 | 0.5 |

| DLY5-10A | 105 | 85 | 75 | 105 | 65 | 57 | 40 | 42.9 | 12 | 2*5 | 4-M5 | 45 | 26.6 | 2 | 6.5 | 8 | 10.5 | 0.5 |

| DLY5-16A | 115 | 100 | 85 | 115 | 70 | 62 | 45 | 48.3 | 14 | 2*6 | 4-M6 | 50 | 29.6 | 2 | 6.5 | 8 | 12.5 | 0.5 |

| DLY5-25A | 125 | 105 | 90 | 125 | 75 | 68 | 50 | 53.6 | 16 | 2*8 | 4-M6 | 58 | 33.9 | 2.5 | 6.5 | 8 | 15.5 | 0.6 |

| DLY5-40A | 140 | 115 | 100 | 140 | 85 | 74 | 60 | 64 | 18 | 2*10 | 6-M6 | 67 | 40 | 2.5 | 7.5 | 10 | 17 | 0.6 |

| DLY5-63A | 160 | 130 | 115 | 160 | 95 | 85 | 70 | 74.3 | 20 | 2*10 | 6-M8 | 75 | 42 | 3 | 7.5 | 10 | 19.5 | 0.7 |

| DLY5-100A | 185 | 155 | 135 | 182 | 115 | 97 | 70 | 74.3 | 20 | 2*12 | 6-M8 | 85 | 49 | 3 | 7.5 | 10 | 21 | 0.7 |

| DLY5-160A | 215 | 180 | 158 | 215 | 130 | 114 | 85 | 95.8 | 22 | 2*12 | 6-M10 | 100 | 58 | 3.5 | 8.5 | 10 | 25.5 | 0.9 |

| DLY5-250A | 250 | 210 | 190 | 250 | 150 | 130 | 85 | 95.8 | 22 | 2*12 | 6-M12 | 115 | 66 | 3.5 | 8.5 | 10 | 26 | 0.9 |

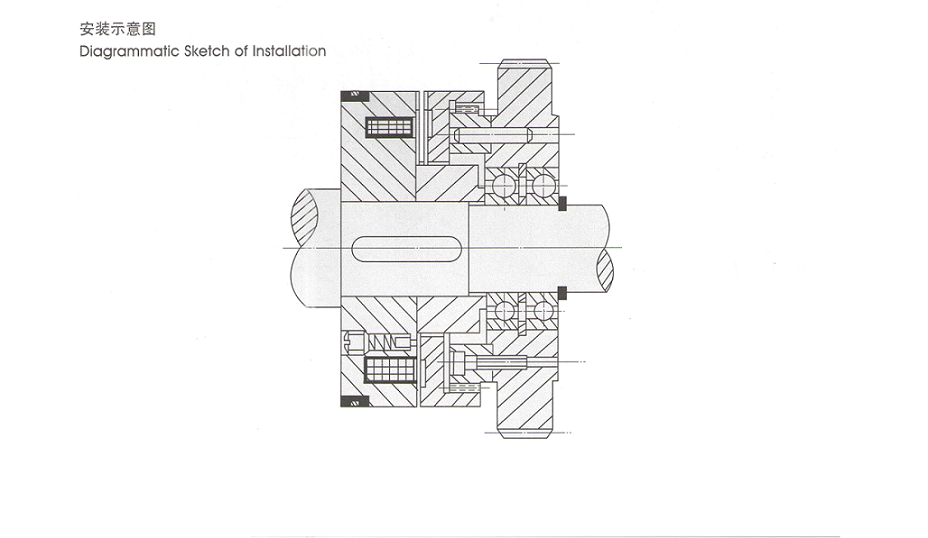

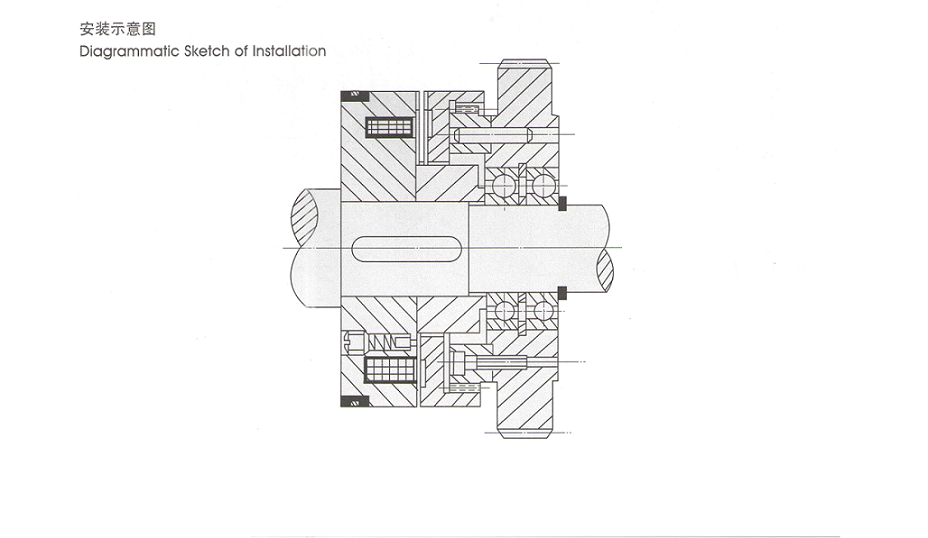

Installation:

1.The clutch can be installed either in horizontal or in verial,If it mounted no the alex,the coaxlal degree between the driving and the driven shaft should not exceed 0.05mm,and must ensure the work clearence value σ.

2.The teeth of both ends should be cleaned before mounting the clutch.

3.The driving and the driven parts of the clutch must be fixed in axial direction,its axial moving doesn't permitted.