Description:

Serpentine spring shaft coupling is a kind of metal elastic coupling with advanced structure. The connection of spring shaft coupling between the prime mover and the working machine is realized by axially embedding the serpentine spring in the tooth groove of the two halves of the coupling. Due to the special performance of the spring, the resonance phenomenon between the prime mover and the working machine is avoided to a large extent, and the service life is much longer than that of the non-metallic elastic element coupling. The size of the contact surface varies with the transmission torque, so it can bear large load variation.

The short-term overload capacity of the reed is 2 ~ 3 times of the rated torque, the transmission efficiency is 99.5%, and the operation is reliable. And the structure of the serpentine spring shaft coupling is simple, convenient assembly and disassembly, allowing large installation deviation, suitable for impact coal crusher, gravel crusher, crank reciprocating movement, mining, heavy machinery, reducer, etc.

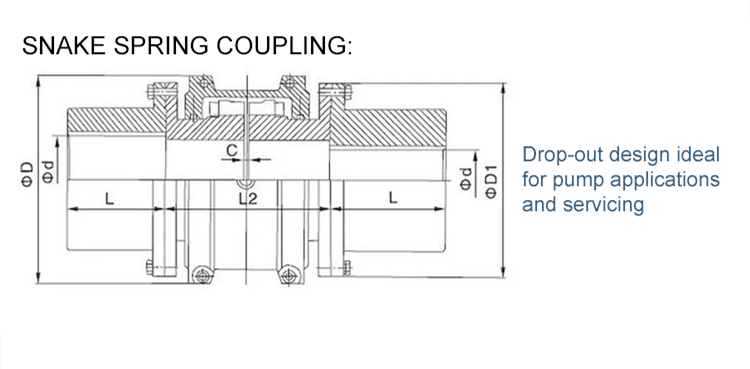

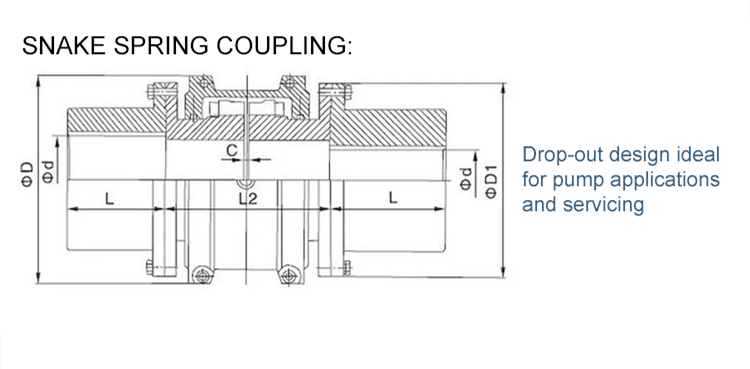

Structure:

1. The oil injection point temperature ≥150℃, can resist centrifugal force, with separation stability, no impurities and will not corrode carbon steel or nitrile rubber lithium grease performance is good.

2. Alignment of the gap and angular deviation between the two valve couplings. When installing, measure the gap between the two valve couplings every 90°, and the difference between the large value and the small value is not more than 0.38mm.

3. Fill it with enough grease. Sufficient grease is very important for the work of the coupling. Annual check-ups are recommended. Pour oil backwards using a dry grease gun until the hole is filled with excess oil.

Features:

1. High strength of elastic element, smaller volume and compact structure than other couplings that transmit the same torque.

2. stable performance, long service life. .

3. manufacturing is more complex, high cost.

4. with high power and high speed pumps and fans, high power internal combustion engines, compressors, gas turbines.

5. Crushing machinery with large impact torque and drastic load change.

6. precision transmission machinery, data transmission system, such as CNC machine tools.

7. high temperature, high precision transmission requirements such as textile, papermaking, printing, packaging machinery.

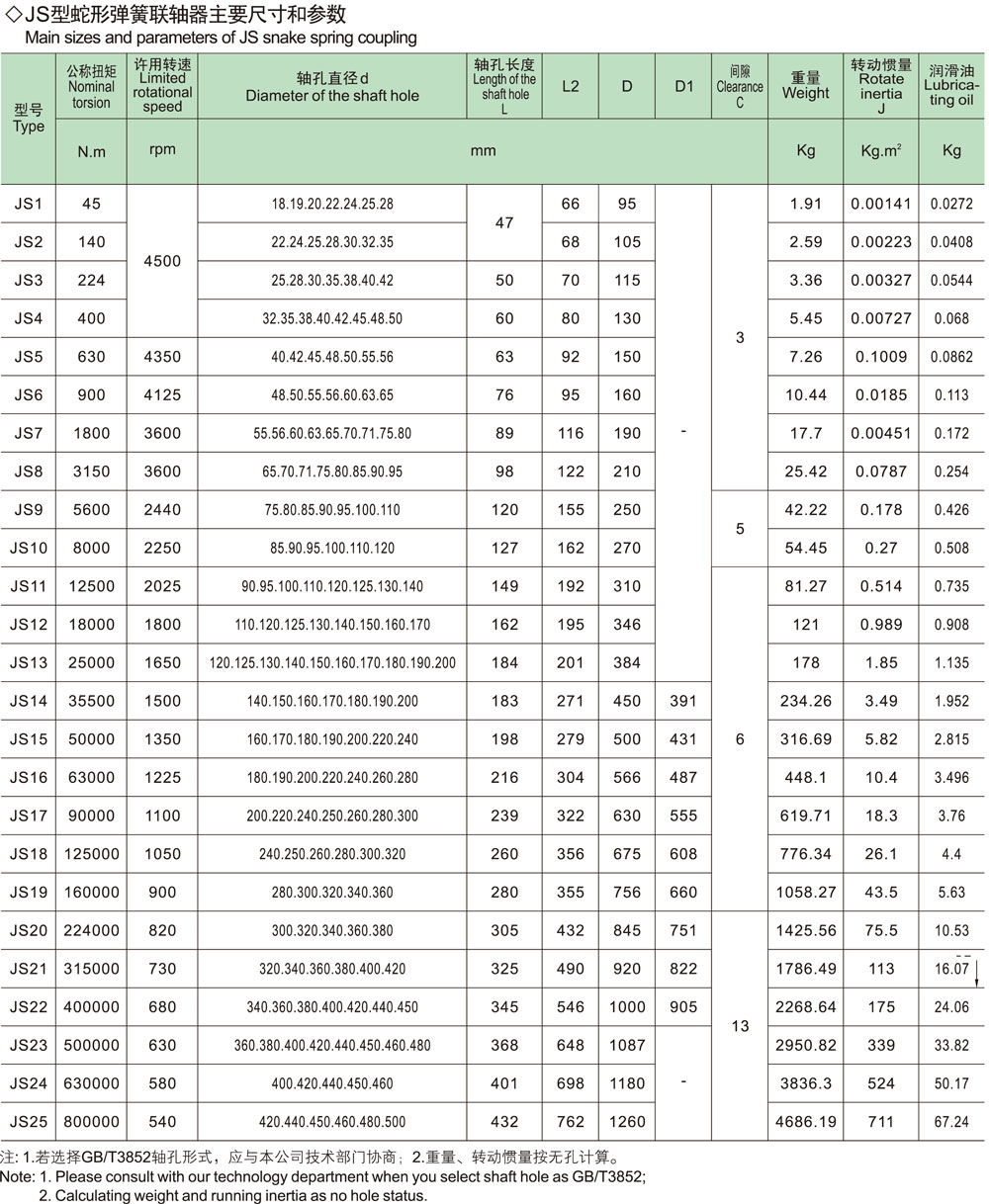

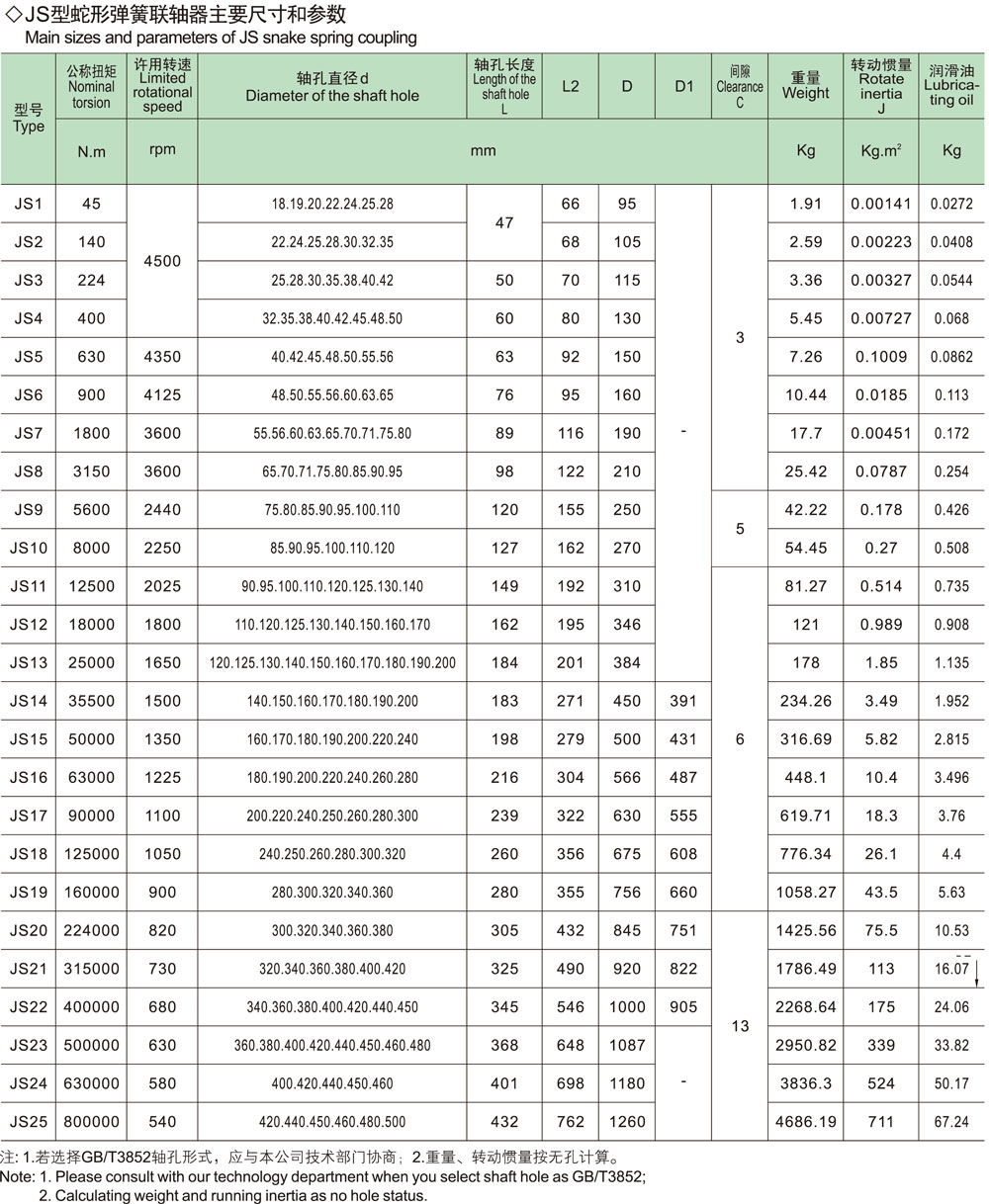

Product parameter: