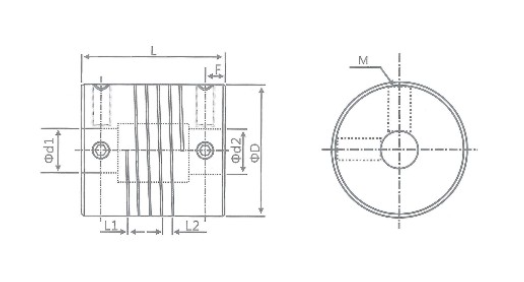

GM screw thread setscrew series coupling winding coupling

>Integrated structure, the overall use of high-strength aluminum alloy materials

>Elastic action compensates radial, angular and axial deviation

>Spring design, with buffer effect

>Special design for encoder, micro motor

>Fastening method of set screw

- Phone: 18019694558

- Email: sales@backstopclutch.com

GM screw thread setscrew series coupling winding coupling

>Integrated structure, the overall use of high-strength aluminum alloy materials

>Elastic action compensates radial, angular and axial deviation

>Spring design, with buffer effect

>Special design for encoder, micro motor

>Fastening method of set screw

- Phone: 18019694558

- Email: sales@backstopclutch.com