Description:

The encoder shaft coupling is actually the spring shaft coupling for encoder. The spring shaft coupling for encoder(encoder shaft coupling) is a metal elastic coupling formed in one piece. The encoder shaft coupling is suitable for shaft connection with small torque and zero rotary clearance. Its elastic action compensates radial, angular and axial deviations. Clockwise and counterclockwise rotation characteristics are exactly the same. There are positioning screws and clamping screws. Suitable for stepper motor, rotary encoder, screw and other connections. (undertake non-calibration to do).

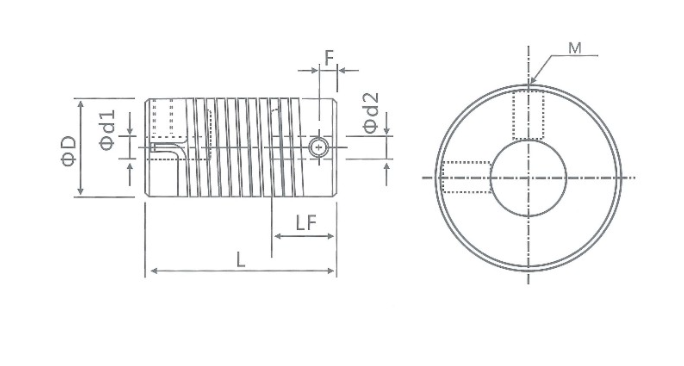

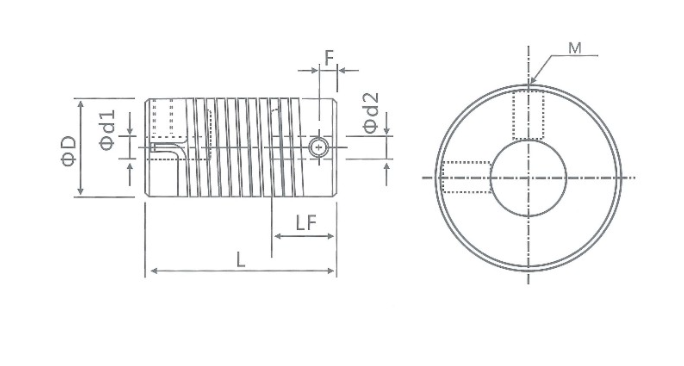

Structure:

Encoder shaft coupling is made of glass fiber material with good flexibility and balance, suitable for encoder connection.

● Encoder shaft coupling with universal rib structure, top wire tensioning.

● The shaft misalignment of encoder shaft coupling is small, with good rotating balance characteristics, and can be coupled with different shaft diameter

● Torsional resistance, can absorb trace axial movement and radial concentricity of the shaft.

RB latch coupling

● Holding type structure, fastening and tensioning.

● Greater torque than RS, diameter ф 20- ф 50, aperture ф 6- ф 30.

Features:

The encoder shaft coupling has the following three characteristics:

1. Zero clearance: the whole encoder coupling is not allowed to have clearance in the transmission process.

2. Low inertia: on the basis of ensuring the transmission strength, the weight of the encoder coupling should be reduced as much as possible.

3. high flexibility: the encoder coupling in the work needs to be largely automatic compensation in the installation process of axial, radial, angular and other deviations.

| model parameter | common bore diameter d1,d2 | ΦD | L | LF | F | M | tightening screw torque

(N.M) |

| GD-16 x27 | 5,6,6.35,7,8,9,10 | 16 | 27 | 8.5 | 3 | M3 | 0.7 |

| GD-16 x35 | 5,6,6.35,7,8,9,10 | 16 | 35 | 12.5 | 3.5 | M4 | 1.7 |

| GD-26 x50 | 6,6.35,7,8,9,10,11,12,12.7,14 | 26 | 50 | 17 | 4.5 | M5 | 4 |

| model parameter | Rated torque

(N.M)* | Maximum torque

(N.M)* | maximum speed

rpm | moment of inertia

(Kg.M2) | allowable eccentricity

(mm)* | allowable deflection angle

(°)* | allowable axial deviation

(mm)* | weight(g) |

| GD-16 x27 | 0.5 | 1 | 3000 | 1.02x10-6 | 1.0 | 8 | ±1.0 | 30 |

| GD-16 x35 | 0.5 | 1 | 3000 | 1.02x10-6 | 1.0 | 8 | ±1.0 | 70 |

| GD-26 x50 | 1.5 | 3 | 3000 | 1.15x10-5 | 1.2 | 8 | ±1.0 | 130 |