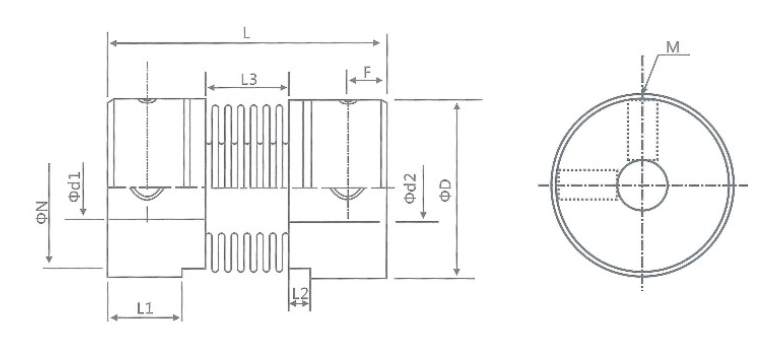

GR Aluminum alloy bellows setscrew coupling

>The material is aluminum alloy, and the middle bellows is made of stainless steel with excellent corrosion resistance

>Laser welding is used between bellows and shaft sleeve, with zero rotation clearance, suitable for forward and reverse rotation

>Bellows structure can effectively compensate radial, angular and axial deviation

>Designed for servo motor stepper motor

>Fastening method of setscrew

- Phone: 18019694558

- Email: sales@backstopclutch.com

GR Aluminum alloy bellows setscrew coupling

>The material is aluminum alloy, and the middle bellows is made of stainless steel with excellent corrosion resistance

>Laser welding is used between bellows and shaft sleeve, with zero rotation clearance, suitable for forward and reverse rotation

>Bellows structure can effectively compensate radial, angular and axial deviation

>Designed for servo motor stepper motor

>Fastening method of setscrew

- Phone: 18019694558

- Email: sales@backstopclutch.com